Safety starts with protecting our healthcare workers.

The healthcare industry is one of the most hazardous environments to work in.

Employees in this industry are constantly exposed to contact, droplet, and airborne hazards. For the safety of our healthcare workers, CDC Guidelines require the use of Personal Protective Equipment (PPE).

Blickman’s PPE protects against these various work hazards. We offer full body coverage from head to toe with bouffant covers, face protectants, gowns, gloves, and shoe covers. Additionally, we offer accessories to aid in personal protection, such as no-touch thermometers, water soluble hamper bags, and disinfectant wipes.

All Blickman PPE is intended for use in the medical industry and meets the specific performance standards for protection in the industry following FDA and CDC guidelines.

Different areas require different levels of protection.

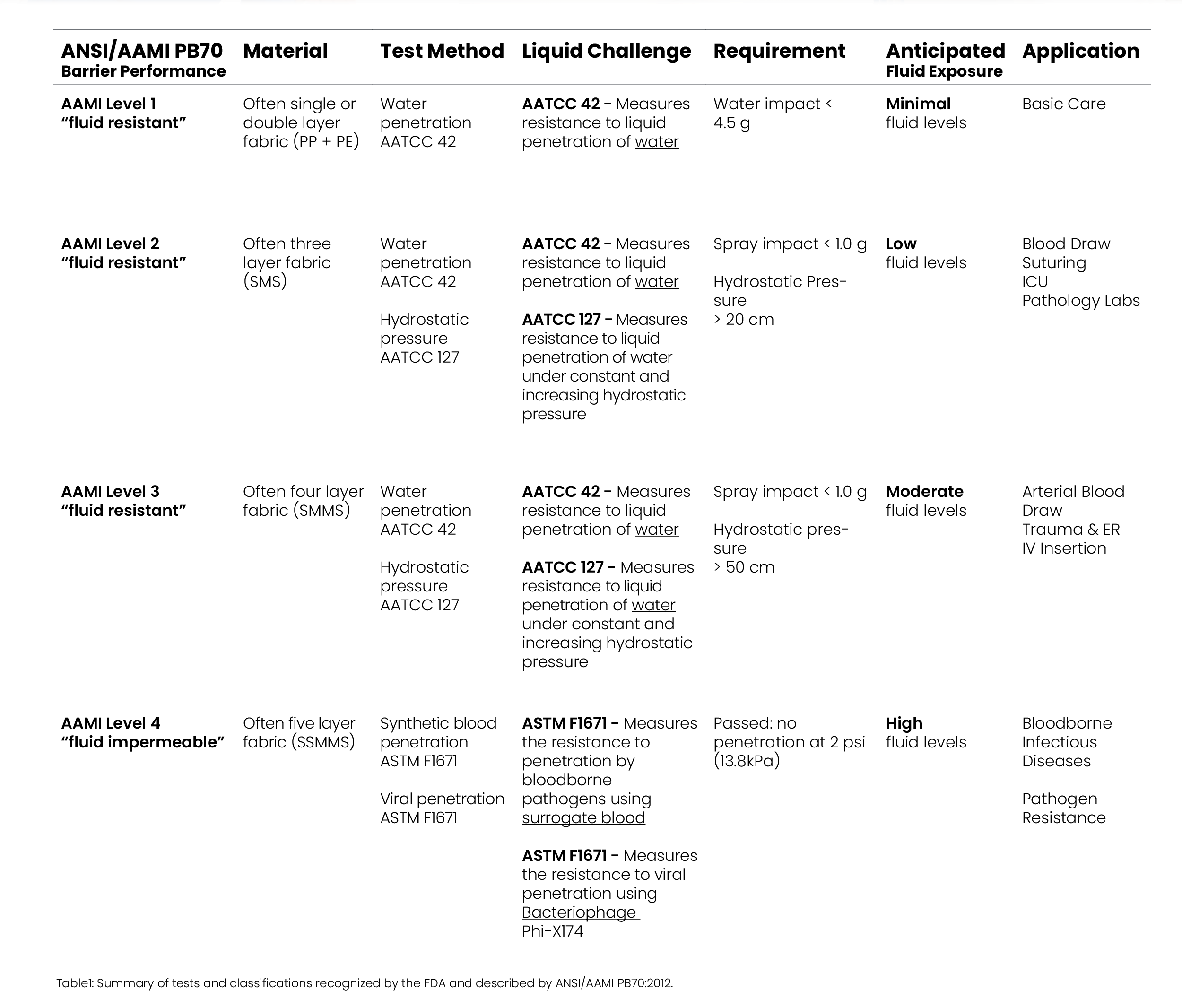

The FDA recognizes standards set forth by the American National Standards Institute (ANSI) and the Association of the Advancement of Medical Instrumentation (AAMI). The ANSI/AAMI specify test methods and performance results that yielded four levels of protection. Level 1 being the lowest level of protection, and Level 4 being the highest.

ANSI/AAMI PB70:2012 describes the liquid barrier performance and classification of protective apparel and drapes intended for use in health care facilities.

PPE Materials (Listed in order of increased protection)

POLYETHYLENE FABRIC

Polyethylene (PE): Single layer of plastic film. Thin, fluid resistant material, much like plastic. Minimal breathability, but very durable.

Chlorinated PE: Chlorinated plastic film. Provides excellent protection at an affordable cost.

POLYPROPYLENE FABRIC

Spunbond Polypropylene (PP): Single layer of 100% polypropylene nonwoven fabric. Soft cloth-like fabric meant for minimal fluid exposures. Affordable, comfortable, and breathable.

Coated Polypropylene (PP+PE): Two layered fabric: soft spunbond polypropylene coated with a layer of polyethylene (plastic) film. Lightweight material with increased fluid resistance (often used for AAMI Level 1 gowns).

SFS Fabric: Three layered fabric: Spunbond PP + Polyester Film + Spunbond PP.

Spunbond PP Advantages: High tensive stretch, flexibility, abrasion resistance, and breathability.

Polyester Film Advantages: Fluid resistant, lightweight, and durable. Optimal combination of protection and comfort (soft, lightweight, strong, fluid resistant, breathable) meant for extended use under low to moderate fluid exposure conditions (often used for AAMI Level 2 and 3 gowns).

SMS Fabric: Three layered, 100% polypropylene fabric: Spunbond PP + Meltblown PP + Spunbond PP.

Spunbond Advantages: High tensive stretch, flexibility, and abrasion resistance.

Meltblown Advantages: Ultrafine pore structure and effective absorption. Optimal combination of protection and comfort (soft, strong, fluid resistant, antistatic, breathable) meant for extended use under low to moderate fluid exposure conditions (often used for AAMI Level 2 and 3 gowns).

Polycoated SMS Fabric: Four layered fabric: SMS fabric coated with a layer of polyethylene (plastic) film. Provides maximum protection from potential hazards associated with handling Chemotherapy agents. This material is used for Chemotherapy gowns and is tested against specific Chemotherapy drugs (see Chemotherapy gowns for more details).

SMMS Fabric: Four layered, 100% PP fabric: Spunbond PP + Meltblown PP x 2 + Spunbond PP. Similar to SMS fabric with an added layer of fluid resistance. Ideal for extended use under moderate to high fluid exposure conditions (often used for AAMI Level 3 and 4 gowns).

Spun-Melt (SSMMS) Fabric: Five layered, 100% Polypropylene fabric: Spunbond PP x 2 + Meltblown PP x 2 + Spunbond PP. This is a strong multilayer fabric with excellent filtration that is ideal for higher levels of fluid exposure (often used for AAMI Level 4 gowns).

Common PPE Level Misconceptions

Protection Level Misunderstanding

A common misunderstanding among many end users is that they are protected from blood, body fluids, and other potential infectious materials, when they wear any type of fluid resistant garment or surgical or isolation gown. ANSI/AAMI PB70 Level 1, 2, and 3 surgical/isolation gown testing requirements only use water as a challenge. Because the surface tension of water is much higher than that of blood; blood can penetrate through fabrics more readily than water. Only Level 4 gowns are tested for viral penetration resistance, and therefore only Level 4 garments are considered impermeable to viral penetration using ASTM F1671.

To learn more about PPE Guidelines please visit: https://www.cdc.gov or https://www.fda.gov